Call: 07971670529

25 kg PE Wax Polymer Additive

Price 140 INR/ Kilograms

MOQ : 500 Kilograms

25 kg PE Wax Polymer Additive Specification

- Particle Size

- Flake size: 2-5 mm

- Moisture Content

- <0.2%

- Acid Resistance

- Excellent

- Molecular Formula

- (C2H4)n

- EINECS No

- 200-815-3

- Length

- Not applicable (flakes)

- Hardness

- 4-6 (D-scale)

- Weight

- 25 kg (bag)

- Ph Level

- High

- Viscosity

- 10-30 cps @ 140C

- Alkali Resistance

- Excellent

- Operating Temperature

- 80C - 200C

- Thickness

- Not applicable (flakes)

- Chemical Name

- Polyethylene Wax

- Other Names

- PE Wax, Polymer Additive

- CAS No

- 9002-88-4

- Purity

- 99%

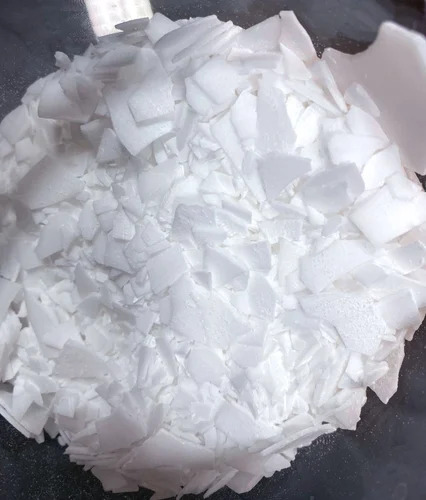

- Appearance

- White

- Physical State

- Flakes

- Raw Material

- Polyethylene

- Molecular Weight

- 2000-4000 g/mol

- Dissolving Time

- Quick (varies with solvent)

- Insoluble %

- <0.1%

- Toxicity

- Non-toxic

- Ash Content

- <0.05%

- Usage

- Polymer additive, lubricity & dispersing agent

- Shelf Life

- 24 months

- Storage Conditions

- Store in a dry, cool place

- Packaging Type

- LDPE Bag

- Odor

- Odorless

- Compatibility

- Compatible with most thermoplastics

- Melting Point

- 100-110°C

25 kg PE Wax Polymer Additive Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About 25 kg PE Wax Polymer Additive

Get impeccable performance with our 25 kg PE Wax Polymer Additive, now available on clearance sale! This classic polyethylene wax boasts a melting point of 100-110C, is virtually odorless, and offers a shelf life of 24 months. Packaged virtuoso-style in LDPE bags, it's designed for easy dispensing and storability. Compatible with most thermoplastics, it's renowned as a non-toxic, high-purity (99%) polymer additive, providing flawless lubricity and dispersing efficiency. Odorless, fast-dissolving, and acid/alkali-resistant-this is the additive every supplier or trader in India needs at unbeatable value.

Application, Users, & Features

Perfect for polymer film, injection molding, and masterbatch, this PE Wax Polymer Additive delivers outstanding lubricity and dispersion on various thermoplastic surfaces. Used by manufacturers, processors, and suppliers in plastics, it also enhances durability and flow. Extra features include high chemical resistance, a compact flake form for quick mixing, and easy integration into existing systems-making it a classic virtuoso for advanced polymer formulations.

Export Markets, Payment, & Domestic Offers

Our 25 kg PE Wax Polymer Additive is in demand in main export markets such as the Middle East, Africa, and Southeast Asia. Shipped swiftly across India, it's dispatched with flexible payment terms including advance payment and secure online transactions. Seize this opportunity to get the lowest price through our clearance offer, available to both large-scale manufacturers and local traders in the main domestic markets.

Application, Users, & Features

Perfect for polymer film, injection molding, and masterbatch, this PE Wax Polymer Additive delivers outstanding lubricity and dispersion on various thermoplastic surfaces. Used by manufacturers, processors, and suppliers in plastics, it also enhances durability and flow. Extra features include high chemical resistance, a compact flake form for quick mixing, and easy integration into existing systems-making it a classic virtuoso for advanced polymer formulations.

Export Markets, Payment, & Domestic Offers

Our 25 kg PE Wax Polymer Additive is in demand in main export markets such as the Middle East, Africa, and Southeast Asia. Shipped swiftly across India, it's dispatched with flexible payment terms including advance payment and secure online transactions. Seize this opportunity to get the lowest price through our clearance offer, available to both large-scale manufacturers and local traders in the main domestic markets.

FAQ's of 25 kg PE Wax Polymer Additive:

Q: How is the PE Wax Polymer Additive typically used in polymer processing?

A: This PE Wax additive is incorporated during polymer blending or processing to improve lubricity and dispersion, making it ideal for injection molding, masterbatch production, and film extrusion.Q: What surfaces and industries most benefit from this PE Wax additive?

A: It works best on thermoplastic surfaces, benefiting industries such as plastics manufacturing, compounding, and converting, where smooth flow and high-quality dispersion are paramount.Q: What process ensures the integration of PE Wax into polymer matrices?

A: The flakes are added during the polymer mixing stage, dissolving quickly depending on the solvent, and dispersing uniformly without agglomeration, even at elevated temperatures.Q: What are the main usage advantages of this PE Wax?

A: Users benefit from its high purity, virtually odorless nature, and exceptional acid and alkali resistance, all contributing to enhanced processing efficiency and better finished product quality.Q: Where can customers in India purchase or get further information about this product?

A: Local suppliers and traders across major Indian markets offer this additive, with direct inquiries available through export channels or domestic distributors specializing in polymer additives.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Polymer Additive Category

50 kg Epoxy Resin A Polymer Additive

Price 65 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Physical State : Liquid

Ph Level : High

Purity : 99%

Color : White

25 kg Zinc Stearate Polymer Additive

Price 120 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Physical State : Powder

Ph Level : High

Purity : 99%

Color : White

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese